28 Jan Design Journey of the S2020 Stool

Designing a New Product: S2020

Originality in the furniture industry is difficult, but that doesn’t mean we don’t try. There are so many behind the scenes decisions to be made about a new product – the target market, the look, the sit, the feel, the function, the materials, the manufacturing process – we thought it would be fun to give you a brief look at to how we bring a new product to life, from original design intent to final production.

For this journey, we decided to document the new S2020 stool, to be introduced at the April 2016 High Point Furniture Market. We began designing the S2020 on January 6th to have ready for a January 27th photoshoot deadline for the High Point Designer Preview Ad. At California House, we always seem to work best under pressure and a tight deadline. It’s like the really good design ideas get diluted towards the mundane the longer we get to work on something. We hope that by explaining some of the details, it will allow you to better understand the intricacies that went into creating your new stool.

We thought it would be fun to give you a brief look at to how we bring a new product to life, from original design intent to final production.

For the new S2020 stool, the design direction was as follows: We wanted something simply styled that would be appropriate in a wide variety of interiors. We wanted the stool to look good in a kitchen as well as bar (counter height as well as bar height), therefore it had to be fairly narrow so homeowners could fit more stools in a smaller area – 18” wide max. Since the stool was to be narrow, it had to be armless. Most importantly, it had to have one distinctive feature that set it apart from all other stools on the market and be extremely comfortable. That’s it. Those were the design instructions given when we set out to build our new stool design.

Our design team always works the same way – quick hand sketches to convey general shapes, then almost immediately a concept is taken into a 3D modeling program so we can see the drawing with more realistic scaling. You would be amazed at how many great looking sketches and designs would be completely inappropriate for a human body. In 3D, we know the ideal pitch angles, depths, heights, etc. and can apply them to our design. All of our earliest prototype revisions, several rounds in fact, happen in the virtual world.

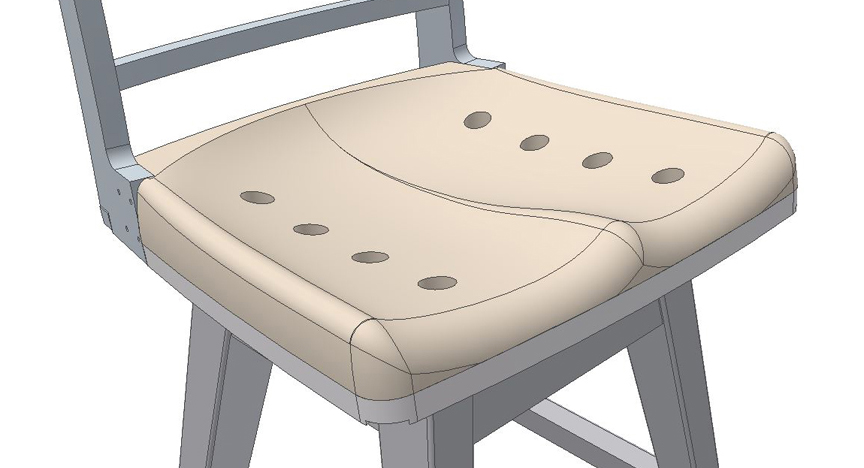

The most important goals for this stool build was to have a unique feature not found in other stools on the market, and make sure the sit was superb. We quickly decided to tie those two directives together and combined the look of a traditionally upholstered seat with a deep, anatomically carved solid seat deck under the foam. We debated as to whether something that made the stool so unique should be added where you can’t see it, but we couldn’t think of any other design on the market with an anatomically shaped seat deck. We also knew that another stool we make, the S110, had a similar anatomically carved solid wood seat and was incredibly comfortable. Imagine if it had a layer of foam on top of the butt-hugging seat. We also thought this hidden detail would allow the stool to develop a “broken-in” look over time where the seat shape could conform to the user like an old favorite chair. We had been playing around with a “breaking-in” as opposed to “wearing out” concept for quite a while and hoped this would apply. We would narrow down foam thicknesses and densities later during the sit testing.

As for the back, we wanted it to be relatively low so that it didn’t take up too much space or block the view in a room, but be high enough to provide support. We also wanted it to be upholstered so that if you accidentally swiveled the back into your counter top it wouldn’t damage either of the pieces.

Finally, the base. It had to swivel. We wanted straight, tapered legs for a clean look that could fit into a wide range of interior styles ranging from soft modern to more traditional and everything in between. Furthermore, we wanted to make sure it looked good in both bar and counter heights. Many stools appear short and stubby at counter height and we wanted this stool to avoid that problem. Almost all swivel bases on the market are symmetrical so the manufacturer can make four of the same legs, stretchers, etc. and save money. Ours quickly became longer front to back than it was wide with differing leg angles. This served two purposes. First, it provided a wider base for better stability front to back. Next, it just flat out looked fantastic. It also meant we would have to make more parts, which costs more. We were ok with that.

After we worked out a few kinks in the virtual 3D world, it was on to physical prototyping. Initial mock-ups take about a day and are simply crude frames screwed together with no glue or mortise & tenons. Foam is set down and our cocoon layer of poly-wrap is stapled in place. Needless to say, it is pretty rudimentary, but not too far off the final shape. We were pleasantly surprised at how strong the base was simply screwed together. As for the sit, the stool sat…different than usual. A bit hard initially, but then it was as if you couldn’t feel any pressure points. It was nice, but we weren’t completely sold. However, the women that sit tested the prototype LOVED it. They said they could feel the contoured seat and that it hugged them perfectly. This was a very good sign and something we could build on. Like with all early prototypes, however, there were issues. The anatomically correct seat placed the user’s rear a bit more forward than usual, which caused the back angle to be too large. The footrest, intentionally high to begin with, was in fact too high and needed to be lowered. All problems were noted.

At this stage in the design process, we typically let an item sit untouched for several days in a very conspicuous place. Everyone walks by, studies the object, takes notes, sits in it, and bounces ideas off one another. Even with our tight deadline, the S2020 was no different. Angles, thicknesses, distances between parts, foam densities, depths, etc. were all slightly altered to make the stool more comfortable and look better in your home. The changes made to the stool during this time were first applied to our 3D model to verify improvement. One of the most notable aesthetic changes made turned out to be both functional and fashionable. We decided to remove the rear stretcher in the base after observing a food server at our favorite bar having to move a stool out of the way to sweep the floor underneath. By removing the rear stretcher, you can get a broom or vacuum completely under and around the stool without having to move it. It was a subtle, but significant design detail that actually enhanced the appearance of the stool as well.

After our alterations and improvements were verified in the virtual world, it was time to make the second physical prototype. The result was a stool that sat really, really well. Not perfect, but getting close. We came up with a really cool way to stretch an elastomeric spring over the anatomically correct seat deck to give us the sit and seat shape we wanted. We also increased the density of the HR foam in the seat. In the back, we added some curvature to the top and removed some from the bottom which created a really nice appearing silhouette. The base was enhanced as well by changing to a thicker leg at the top and altering the footrest height. We knew that with some minor modifications, we were getting close to the correct shape, size, and feel of the seat and back unit. It took two more iterations before we settled on the perfect piece.

With the major structure and silhouette in hand, it was now time to move onto the upholstery details. We wanted the S2020 to have a very clean, simple line. Because of that, we made the decision to eliminate all welting and go with a baseball style top-stitch throughout. The original box seat (top stitch all the way around the front of the seat) was changed to a waterfall style to match the back. It took a few rounds to get the upholstery the way we wanted it, but once we saw what turned out to be the final prototype, we knew it was the look and feel we were after.

In all, the S2020 took a team of four people just under two weeks to design from scratch. We had a general concept of style (simple) with a few key parameters (one unique distinctive element, supremely comfortable, smaller scale). With these ingredients, the S2020 was born. We hope you get as much enjoyment sitting in it as we did developing it.